Image 1 of 9

Image 1 of 9

Image 2 of 9

Image 2 of 9

Image 3 of 9

Image 3 of 9

Image 4 of 9

Image 4 of 9

Image 5 of 9

Image 5 of 9

Image 6 of 9

Image 6 of 9

Image 7 of 9

Image 7 of 9

Image 8 of 9

Image 8 of 9

Image 9 of 9

Image 9 of 9

LEADWELL MCV-1500ER VERTICAL MACHINING CENTER

FOR SALE: LEADWELL MCV-1500ER VERTICAL MACHINING CENTER – HEAVY-DUTY CNC MILLING MACHINE

We are offering a Leadwell MCV-1500ER Vertical Machining Center, a reliable, rigid, and production-grade CNC milling machine equipped with the robust FANUC 0-M CNC control.

This machine is designed for precision milling, heavy cuts, mold work, fabrication, tool-room operations, and industrial machining.

The MCV-1500ER features a large 66.75" × 25.75" table, long X-axis travel, a powerful CAT-50 spindle taper for heavy-duty cutting, and a 30-tool automatic tool changer, making it suitable for large components and continuous production environments.

MACHINE SPECIFICATIONS

Manufacturer: Leadwell

Model: MCV-1500ER

Serial Number: N/A

Control: FANUC 0-M CNC Control

TRAVELS & CAPACITY

Table Size: 66.75” × 25.75”

(Approx. 1695 mm × 654 mm)X-Axis Travel: 59” (Approx. 1500 mm)

Y-Axis Travel: 39” (Approx. 990 mm)

Z-Axis Travel: Varies by configuration (spec available on request)

Table Load Capacity: Heavy-duty machine table suitable for large workpieces (spec available on request)

SPINDLE

Spindle Taper: CAT 50 (High-rigidity, heavy milling capability)

Spindle Speed: Typically up to 6,000 RPM (confirmable if needed)

Spindle Motor: Heavy-duty motor suitable for demanding cuts

Drive: Belt / Gear-driven depending on build year (confirmable)

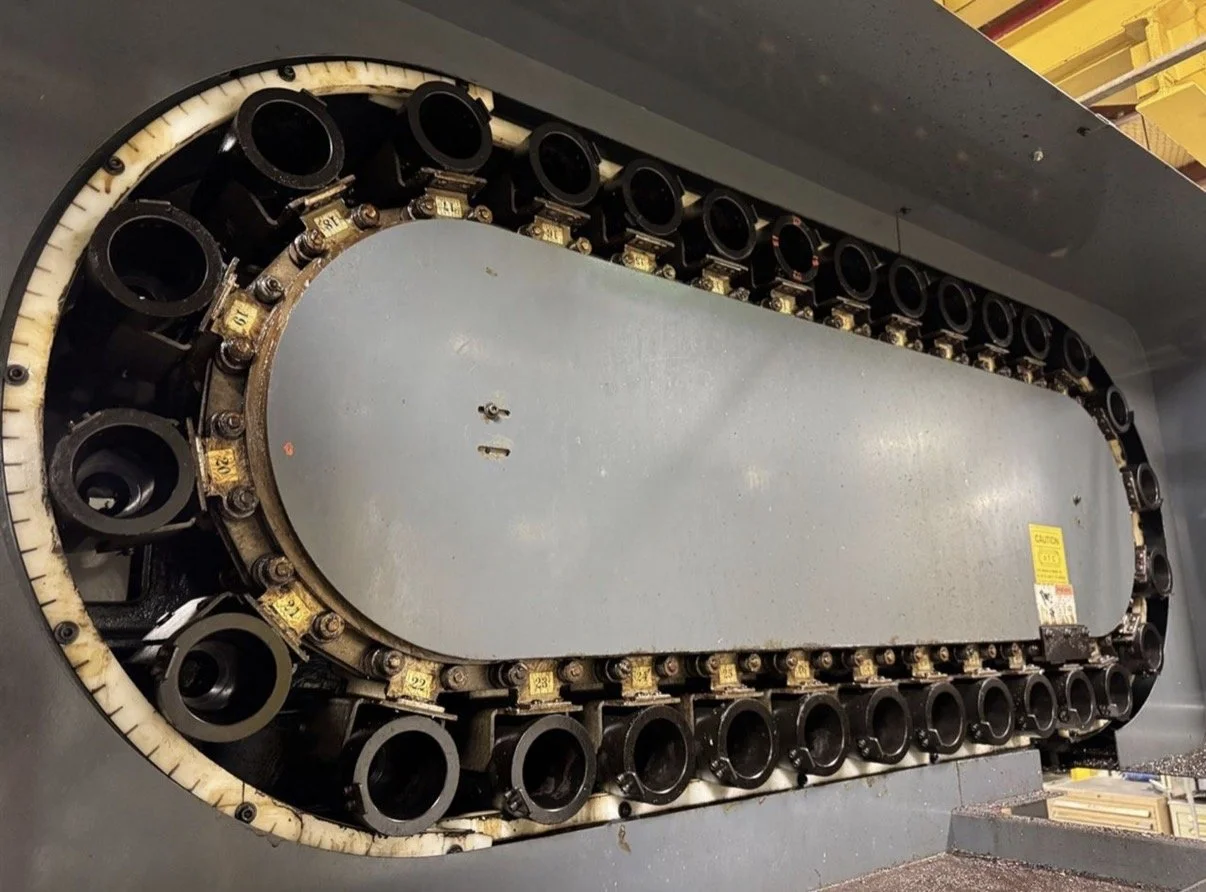

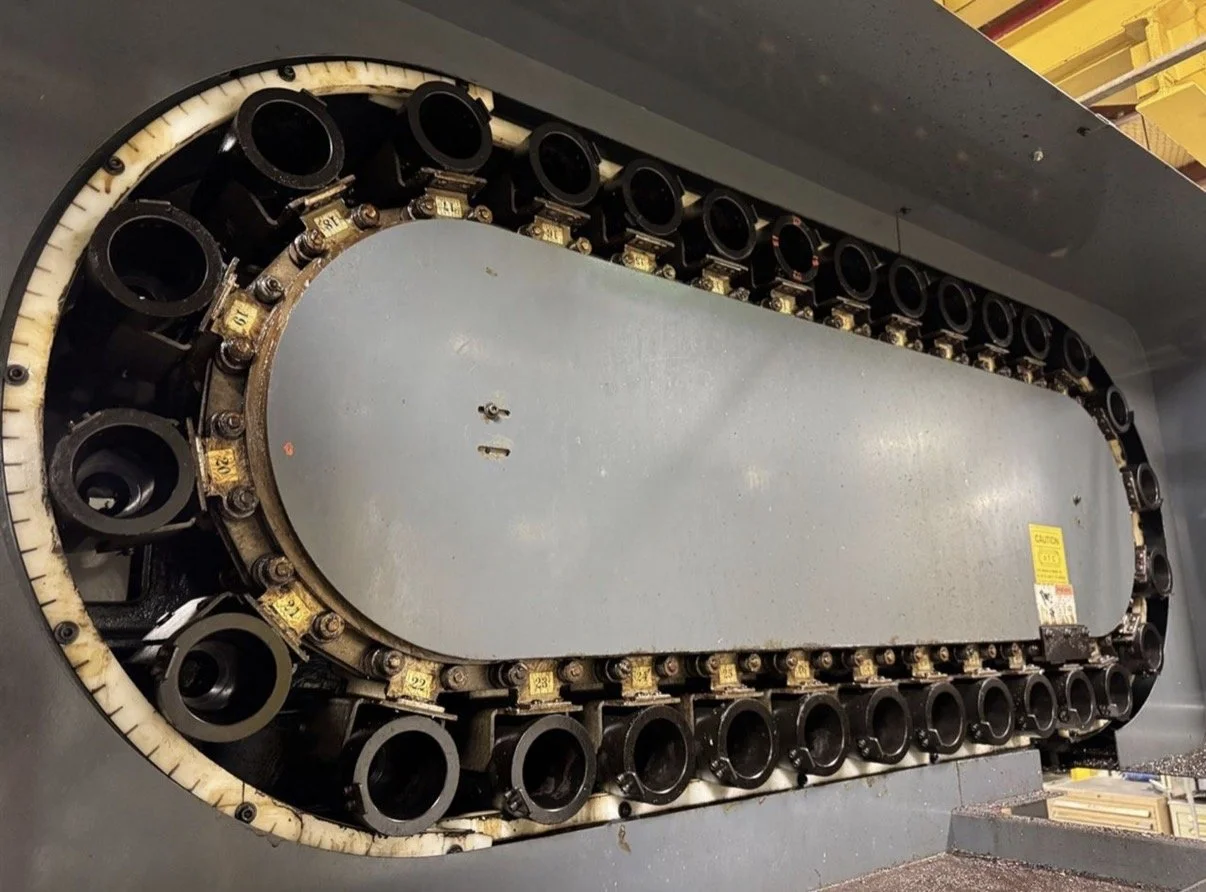

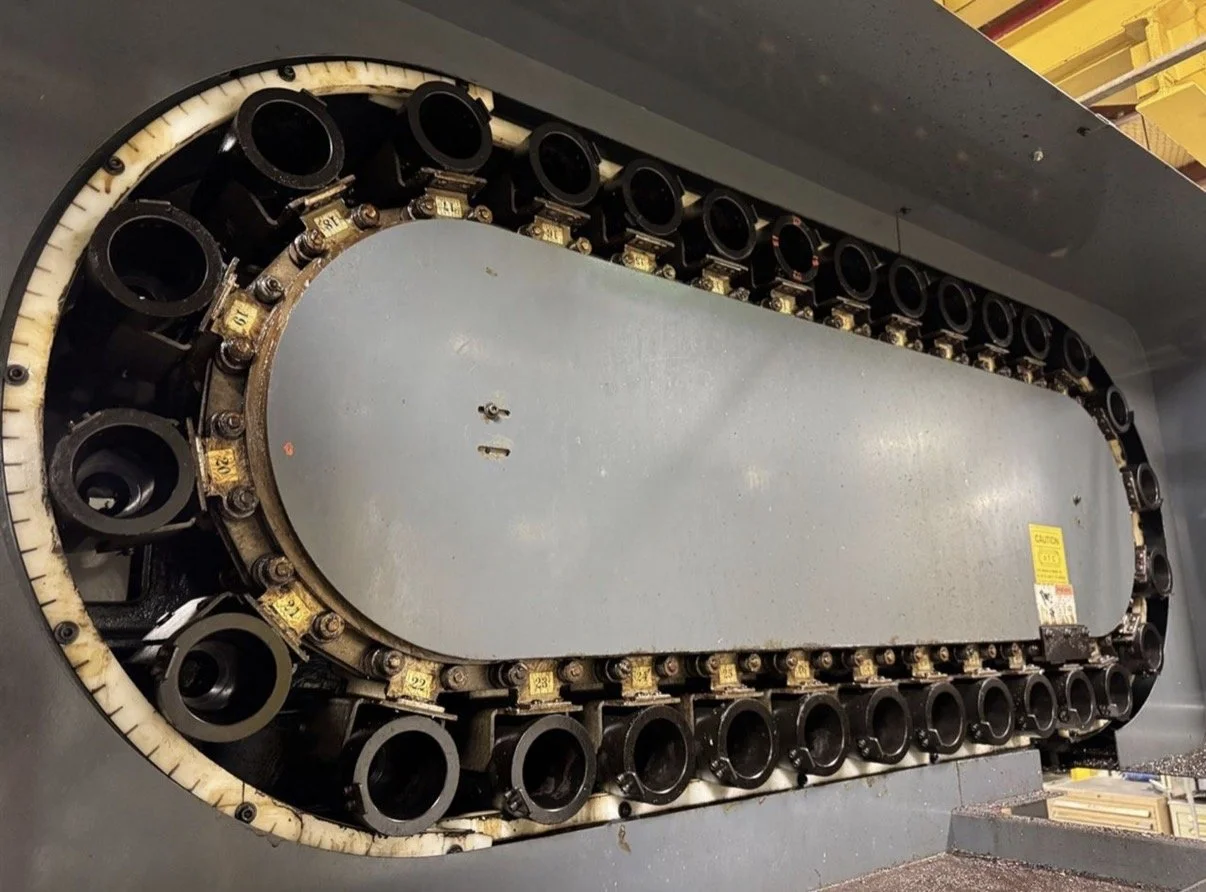

AUTOMATIC TOOL CHANGER

ATC Capacity: 30 Tools

Tool Type: CAT-50

Tool Change Style: Carousel / Arm (depending on configuration)

FEED RATES & PERFORMANCE

Rapid Traverse (X/Y/Z): Typically 20–24 m/min (varies by configuration)

Cutting Feed Rate: Fanuc-controlled variable feed

Positioning Accuracy: High accuracy with FANUC 0-M control

ELECTRICAL

Voltage: 220/480V

Phase: 3-Phase

Frequency: 50/60 Hz

(Exact electrical plate details available on request)

MACHINE WEIGHT & DIMENSIONS

Approx. Weight: Typically 18,000–22,000 lbs (8,200–10,000 kg)

(Varies depending on options; can verify if needed)Overall Dimensions: Provided upon request

MACHINE IS EQUIPPED WITH

FANUC 0-M CNC Control

30-Tool Automatic Tool Changer

CAT-50 Spindle Taper

Large 66.75” × 25.75” Table

Full Enclosure (if applicable)

Coolant System

Chip Auger / Chip Conveyor (optional depending on machine)

Worklight, Handwheels, and Standard Accessories

MACHINE OVERVIEW

The Leadwell MCV-1500ER is known for its rigid construction, large working envelope, and ability to take heavy cuts with its CAT-50 taper.

This model is ideal for:

✔ Mold & die making

✔ Precision machining

✔ Fabrication & tool-room work

✔ Industrial part production

✔ Large plate machining

✔ Steel, alloy, and cast-iron jobs

FANUC 0-M control ensures reliability, easy programming, stable operation, and global spare-parts availability.

This machine is clean, fully functional, and ready for inspection or immediate shipment.

FOR SALE: LEADWELL MCV-1500ER VERTICAL MACHINING CENTER – HEAVY-DUTY CNC MILLING MACHINE

We are offering a Leadwell MCV-1500ER Vertical Machining Center, a reliable, rigid, and production-grade CNC milling machine equipped with the robust FANUC 0-M CNC control.

This machine is designed for precision milling, heavy cuts, mold work, fabrication, tool-room operations, and industrial machining.

The MCV-1500ER features a large 66.75" × 25.75" table, long X-axis travel, a powerful CAT-50 spindle taper for heavy-duty cutting, and a 30-tool automatic tool changer, making it suitable for large components and continuous production environments.

MACHINE SPECIFICATIONS

Manufacturer: Leadwell

Model: MCV-1500ER

Serial Number: N/A

Control: FANUC 0-M CNC Control

TRAVELS & CAPACITY

Table Size: 66.75” × 25.75”

(Approx. 1695 mm × 654 mm)X-Axis Travel: 59” (Approx. 1500 mm)

Y-Axis Travel: 39” (Approx. 990 mm)

Z-Axis Travel: Varies by configuration (spec available on request)

Table Load Capacity: Heavy-duty machine table suitable for large workpieces (spec available on request)

SPINDLE

Spindle Taper: CAT 50 (High-rigidity, heavy milling capability)

Spindle Speed: Typically up to 6,000 RPM (confirmable if needed)

Spindle Motor: Heavy-duty motor suitable for demanding cuts

Drive: Belt / Gear-driven depending on build year (confirmable)

AUTOMATIC TOOL CHANGER

ATC Capacity: 30 Tools

Tool Type: CAT-50

Tool Change Style: Carousel / Arm (depending on configuration)

FEED RATES & PERFORMANCE

Rapid Traverse (X/Y/Z): Typically 20–24 m/min (varies by configuration)

Cutting Feed Rate: Fanuc-controlled variable feed

Positioning Accuracy: High accuracy with FANUC 0-M control

ELECTRICAL

Voltage: 220/480V

Phase: 3-Phase

Frequency: 50/60 Hz

(Exact electrical plate details available on request)

MACHINE WEIGHT & DIMENSIONS

Approx. Weight: Typically 18,000–22,000 lbs (8,200–10,000 kg)

(Varies depending on options; can verify if needed)Overall Dimensions: Provided upon request

MACHINE IS EQUIPPED WITH

FANUC 0-M CNC Control

30-Tool Automatic Tool Changer

CAT-50 Spindle Taper

Large 66.75” × 25.75” Table

Full Enclosure (if applicable)

Coolant System

Chip Auger / Chip Conveyor (optional depending on machine)

Worklight, Handwheels, and Standard Accessories

MACHINE OVERVIEW

The Leadwell MCV-1500ER is known for its rigid construction, large working envelope, and ability to take heavy cuts with its CAT-50 taper.

This model is ideal for:

✔ Mold & die making

✔ Precision machining

✔ Fabrication & tool-room work

✔ Industrial part production

✔ Large plate machining

✔ Steel, alloy, and cast-iron jobs

FANUC 0-M control ensures reliability, easy programming, stable operation, and global spare-parts availability.

This machine is clean, fully functional, and ready for inspection or immediate shipment.