We are offering a Hardinge Conquest 42 CNC Turning Center, a high-accuracy, production-grade CNC lathe renowned worldwide for precision, repeatability, and superior surface finishes. This machine is equipped with a GE FANUC Series 18-T CNC control, providing reliable operation, fast processing, and industry-standard G-code programming.

The Conquest 42 is designed for high-speed, tight-tolerance turning applications and is ideal for bar work, small-to-medium parts, and continuous production environments. With a collet chuck, automatic turret, tailstock, and bar feeder, this machine is well-suited for unattended machining and high-volume output.

Manufacturer: Hardinge

Model: Conquest 42

Machine Type: CNC Turning Center

Model Code: SG-42

Control: GE FANUC Series 18-T CNC Control

Maximum Turning Diameter: (Specification available on request)

Maximum Turning Length: (Specification available on request)

Chuck Type: Collet Chuck – ideal for high-precision bar work

Tailstock: Yes – supports longer or heavier components

Turret Type: Automatic Turret

Number of Stations: (Typical Conquest 42 configuration – confirmable)

Tooling Style: Standard turning tool holders

Designed for fast tool changes and reduced cycle times in production machining.

Bar Feeder: Yes – included

Allows continuous bar-stock machining, increased productivity, and reduced operator intervention.

Rapid Traverse: FANUC-controlled high-speed rapids

Cutting Feed Rate: Programmable via FANUC control

Accuracy & Repeatability: Exceptional precision and thermal stability

Control System: GE FANUC Series 18-T

Voltage: Industrial voltage (details available on request)

Phase: 3-Phase

Frequency: 50/60 Hz

✔ GE FANUC Series 18-T CNC Control

✔ Collet Chuck

✔ Automatic Turret

✔ Tailstock

✔ Bar Feeder

✔ Coolant System

✔ Standard Safety Guards & Accessories

The Hardinge Conquest 42 is recognized for its unmatched precision, rigid construction, and long-term reliability. It is an excellent choice for:

✔ High-precision CNC turning

✔ Bar-fed production work

✔ Medical, aerospace & automotive components

✔ Tight-tolerance parts

✔ Continuous production machining

With the GE FANUC Series 18-T control, this machine delivers stable performance, easy programming, and global parts support.

This machine is fully functional, well-maintained, and available for inspection or immediate shipment.

We are offering a Cincinnati FTV 840 CNC Vertical Machining Center, a robust and reliable CNC milling machine built for high-accuracy, continuous industrial production. This machine is equipped with a powerful SIEMENS CNC control, known for precision motion control, advanced machining capabilities, and long-term reliability.

The FTV 840 features a rigid cast-iron construction, generous axis travels, and a production-grade spindle, making it suitable for precision milling, heavy cutting, fabrication, and general CNC machining. This model is well-regarded in industrial environments for its stability, accuracy, and dependable performance.

Manufacturer: Cincinnati

Model: FTV 840

Machine Type: Vertical Machining Center

Model Code: EKT

Serial Number: 7078-A00-K00093

Control: SIEMENS CNC Control

X-Axis Travel: Approx. 840 mm

Y-Axis Travel: Approx. 510 mm

Z-Axis Travel: Approx. 510 mm

(Exact travels can be confirmed upon request)

Table Size: Production-size machine table (spec available on request)

Table Load Capacity: Suitable for medium-to-heavy workpieces

Spindle Taper: (Commonly CAT 40 – confirmable)

Spindle Speed: Production-grade RPM range (spec available on request)

Spindle Motor: High-torque motor for continuous machining

Drive Type: Direct / Belt-driven depending on configuration

Designed for both precision finishing and heavy milling operations.

ATC Type: Automatic Tool Changer

Tool Capacity: (Typical FTV series configuration – confirmable)

Tool Interface: Compatible with standard industrial tooling

Supports efficient tool changes and reduced cycle times in production environments.

Rapid Traverse (X/Y/Z): High-speed CNC-controlled rapids

Cutting Feed Rate: SIEMENS-controlled variable feed

Accuracy: High positioning accuracy and repeatability

Control System: SIEMENS CNC

Voltage: Industrial voltage (details available on request)

Phase: 3-Phase

Frequency: 50/60 Hz

Approx. Weight: Heavy-duty industrial machine (exact weight available on request)

Overall Dimensions: Provided upon request

✔ SIEMENS CNC Control

✔ Vertical Machining Configuration

✔ Automatic Tool Changer

✔ Rigid Cast-Iron Construction

✔ Coolant System

✔ Full Enclosure (if applicable)

✔ Standard Safety Guards & Accessories

The Cincinnati FTV 840 is known for its strong construction, smooth axis motion, and reliable machining performance. It is an excellent choice for:

✔ Precision CNC milling

✔ Production machining

✔ Fabrication & tool-room work

✔ Industrial component manufacturing

✔ Steel, alloy, and cast-iron machining

The SIEMENS CNC control delivers advanced control functionality, stable operation, and excellent motion accuracy, making this machine ideal for demanding shop-floor environments.

This machine is fully functional, well-maintained, and available for inspection or immediate shipment.

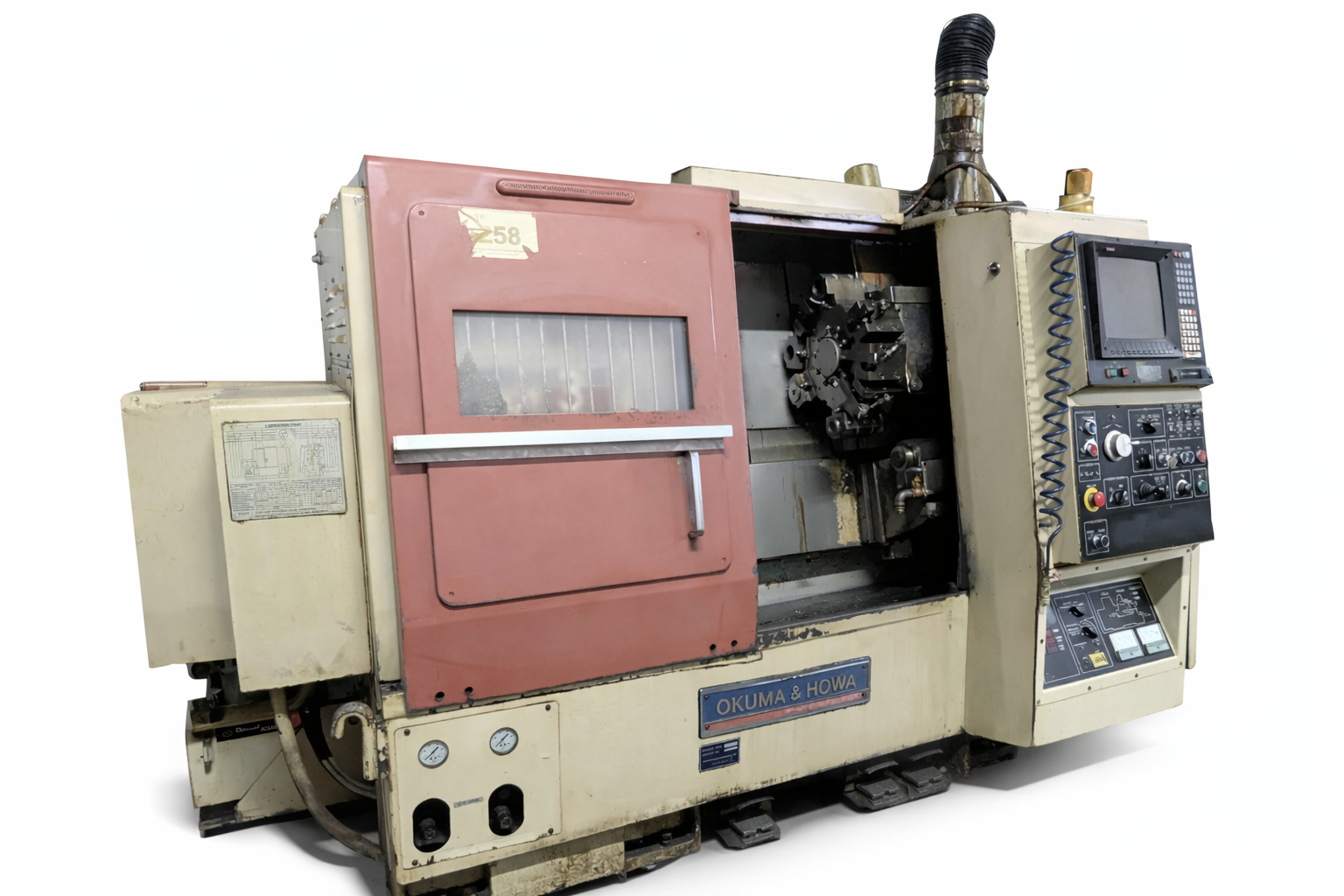

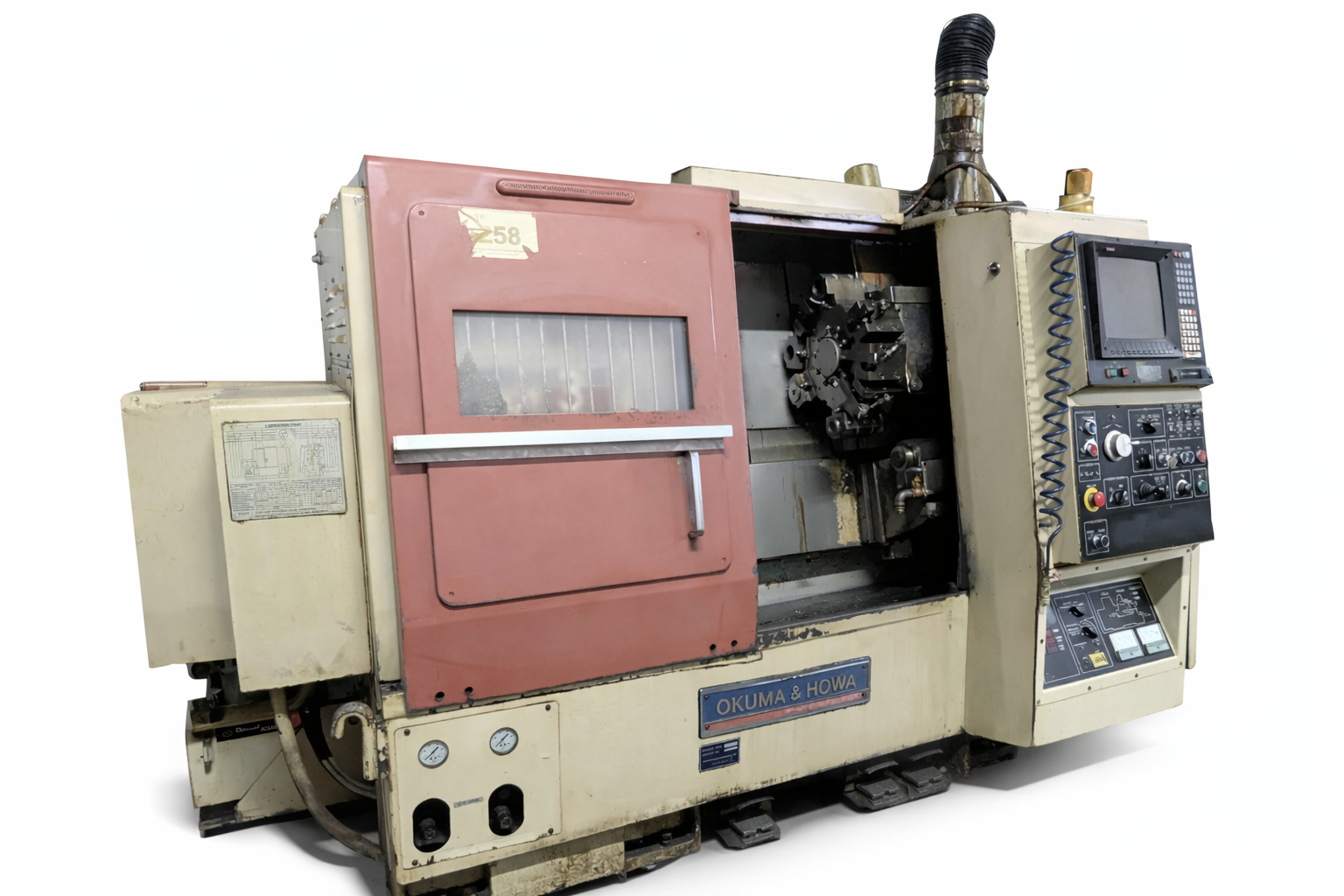

We are offering an Okuma & Howa ACT-3 CNC Turning Center, a solid and dependable CNC lathe built with Japanese engineering precision and designed for consistent, accurate production machining.

This machine is equipped with a proven FANUC CNC control and is ideal for general turning, shaft work, batch production, and industrial machining applications.

The ACT-3 features a rigid machine structure, turret tool system, and tailstock support, making it suitable for both short and long workpieces. With a chip conveyor for efficient chip removal and standard workholding included, this machine is ready for shop-floor production.

Manufacturer: Okuma & Howa

Model / Type: ACT-3

Machine Number: 09257

Control: FANUC CNC Control

Maximum Turning Diameter: (Specification available on request)

Maximum Turning Length: (Specification available on request)

Tailstock: Yes – supports long or heavy workpieces

Chuck: 3-Jaw Chuck

Turret Type: Automatic Turret

Number of Stations: (Typical ACT-3 configuration – confirmable)

Tooling Style: Standard turning tool holders

Designed for efficient tool changes and continuous production cycles.

Rapid Traverse: FANUC-controlled (specs vary by configuration)

Cutting Feed Rate: Programmable via FANUC control

Accuracy & Repeatability: High reliability for production turning

Transformer: JVC Transformer

Voltage: Shop-ready (exact electrical plate details available on request)

Phase: 3-Phase

Frequency: 50/60 Hz

Chip Conveyor: Yes – included

Ensures clean operation and uninterrupted machining during extended runs.

✔ FANUC CNC Control

✔ Automatic Turret

✔ Tailstock

✔ 3-Jaw Chuck

✔ Chip Conveyor

✔ JVC Transformer

✔ Standard Guards & Safety Features

The Okuma & Howa ACT-3 is known for its durability, stable cutting performance, and long service life. It is an excellent choice for:

✔ General CNC turning

✔ Production machining

✔ Shaft and cylindrical components

✔ Steel, alloy, and cast-iron parts

✔ Job shops and industrial manufacturing

With its FANUC control, the machine offers easy programming, dependable operation, and global parts support.

This machine is fully functional, well-maintained, and available for inspection or immediate shipment.

We are offering a 2005 Mazak QTN-250 CNC Turning Center, a versatile, production-ready CNC lathe equipped with reliable Mazatrol Nexus 640T CNC control. This machine is designed for precision turning, batch production, and complex part machining with a robust 12-station turret and substantial work envelope.

Built for industrial turning applications, the QTN-250 is ideal for general turning, light milling/drilling on the turret, fabrication, and continuous production work manufacturing shafts, flanges, housings, and more.

Manufacturer: Mazak

Model: QTN-250

Year: 2005

Serial Number: Confirmable on request

Control: Mazatrol Nexus 640T CNC Control

Swing Over Bed: 26.5" (Approx. 673 mm)

Max Turning / Machining Diameter: 14.75" (Approx. 375 mm)

X-Axis Travel: 9.05" (Approx. 230 mm)

Z-Axis Travel: 22.63" (Approx. 575 mm)

Max Turning / Cutting Length: 19.9" (Approx. 505 mm)

Bar Capacity / Spindle Bore: ~3.03" (Approx. 77 mm)

Chuck Size: 10" (Approx. 254 mm)

Spindle Nose: A2-8

Spindle Speed: Up to 4,000 RPM

Spindle Motor: ~35 HP (26 kW) main spindle

Spindle Type: Hydraulic 3-jaw chuck mounted

(This provides strong torque for heavy turning operations)

Turret Capacity: 12 Stations

Tool Style: Square tool holders (live tooling optional/configurable)

Tool Change Style: Auto-indexing turret

Live Tool Capability: Available on some configurations (confirmable)

Rapid Traverse (X/Z): Approx. 1,181 IPM (30 m/min)

Cutting Feed Range: Mazatrol-controlled variable feed

Positioning & Accuracy: High precision via Nexus CNC control suite

Voltage: Typically 220/480V

Phase: 3-Phase

Frequency: 50/60 Hz

(Exact electrical plate details available on request)

Approx. Weight: ~11,500 lb (Approx. 5,200 kg)

Overall Footprint: ~115" × 70" × 72" (Approx. 2,920 × 1,780 × 1,830 mm)

(Exact dimensions and shipping weight can be provided on request)

Mazatrol Nexus 640T CNC Control

12-Station Auto-Indexing Turret

10" Hydraulic Chuck

Tailstock Support

Chip Conveyor (side disposal)

Bar Feeder Interface (as equipped)

Flood Coolant System

Standard Tool Holders & Manual Files (confirmable)

The Mazak QTN-250 CNC Turning Center is a rigid, production-capable lathe known for its reliable Mazatrol control, versatile turret, and strong mainspeed performance — making it ideal for:

✔ Medium-batch turning & production runs

✔ Complex shaft and feature machining

✔ Shaft, flange & housing manufacturing

✔ Precision engineering and high repeatability work

With Mazatrol Nexus 640T control, this lathe offers stable operation, easy programming, and excellent service support worldwide — ideal for machine shops, OEM production, and contract manufacturers.

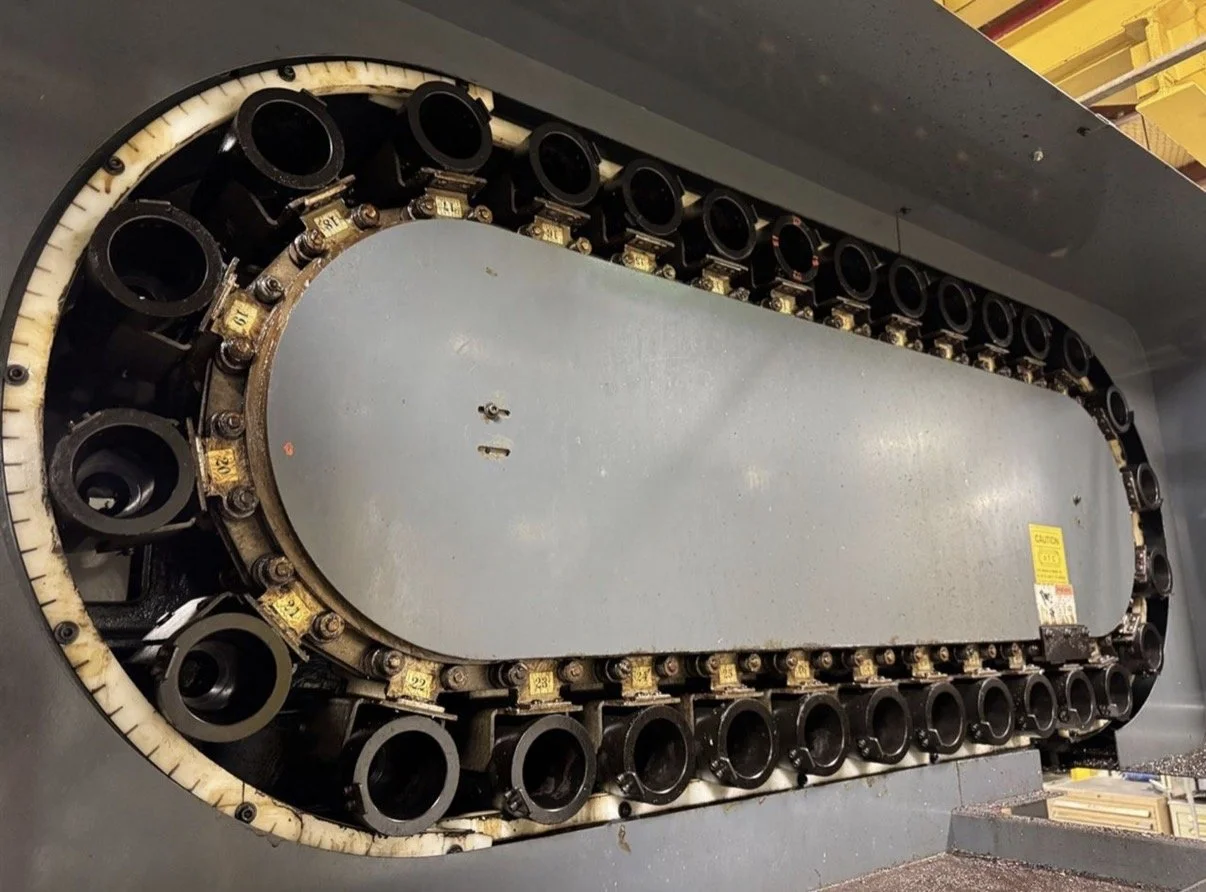

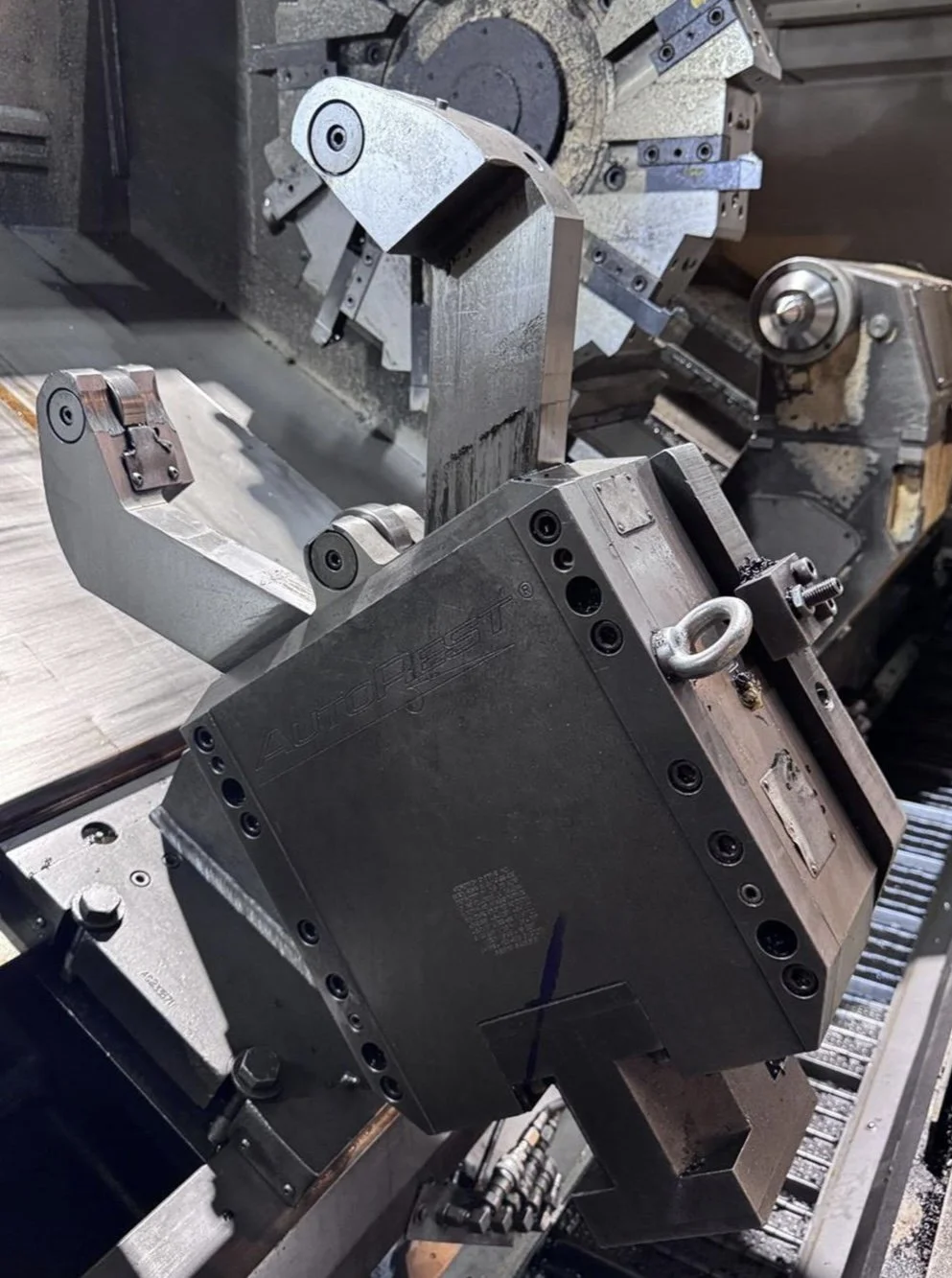

We are offering a Leadwell MCV-1500ER Vertical Machining Center, a reliable, rigid, and production-grade CNC milling machine equipped with the robust FANUC 0-M CNC control.

This machine is designed for precision milling, heavy cuts, mold work, fabrication, tool-room operations, and industrial machining.

The MCV-1500ER features a large 66.75" × 25.75" table, long X-axis travel, a powerful CAT-50 spindle taper for heavy-duty cutting, and a 30-tool automatic tool changer, making it suitable for large components and continuous production environments.

Manufacturer: Leadwell

Model: MCV-1500ER

Serial Number: N/A

Control: FANUC 0-M CNC Control

Table Size: 66.75” × 25.75”

(Approx. 1695 mm × 654 mm)

X-Axis Travel: 59” (Approx. 1500 mm)

Y-Axis Travel: 39” (Approx. 990 mm)

Z-Axis Travel: Varies by configuration (spec available on request)

Table Load Capacity: Heavy-duty machine table suitable for large workpieces (spec available on request)

Spindle Taper: CAT 50 (High-rigidity, heavy milling capability)

Spindle Speed: Typically up to 6,000 RPM (confirmable if needed)

Spindle Motor: Heavy-duty motor suitable for demanding cuts

Drive: Belt / Gear-driven depending on build year (confirmable)

ATC Capacity: 30 Tools

Tool Type: CAT-50

Tool Change Style: Carousel / Arm (depending on configuration)

Rapid Traverse (X/Y/Z): Typically 20–24 m/min (varies by configuration)

Cutting Feed Rate: Fanuc-controlled variable feed

Positioning Accuracy: High accuracy with FANUC 0-M control

Voltage: 220/480V

Phase: 3-Phase

Frequency: 50/60 Hz

(Exact electrical plate details available on request)

Approx. Weight: Typically 18,000–22,000 lbs (8,200–10,000 kg)

(Varies depending on options; can verify if needed)

Overall Dimensions: Provided upon request

FANUC 0-M CNC Control

30-Tool Automatic Tool Changer

CAT-50 Spindle Taper

Large 66.75” × 25.75” Table

Full Enclosure (if applicable)

Coolant System

Chip Auger / Chip Conveyor (optional depending on machine)

Worklight, Handwheels, and Standard Accessories

The Leadwell MCV-1500ER is known for its rigid construction, large working envelope, and ability to take heavy cuts with its CAT-50 taper.

This model is ideal for:

✔ Mold & die making

✔ Precision machining

✔ Fabrication & tool-room work

✔ Industrial part production

✔ Large plate machining

✔ Steel, alloy, and cast-iron jobs

FANUC 0-M control ensures reliability, easy programming, stable operation, and global spare-parts availability.

This machine is clean, fully functional, and ready for inspection or immediate shipment.

We are offering a high-performance OKUMA LB45II CNC Turning Center, engineered for precision machining, stability, and heavy-duty production.

Built in Japan, this model features a rigid flatbed structure, powerful spindle drive, and the reliable OSP-U100L CNC controller, making it ideal for large workpieces, shafts, rollers, and long components requiring tight tolerances and consistent surface finish.

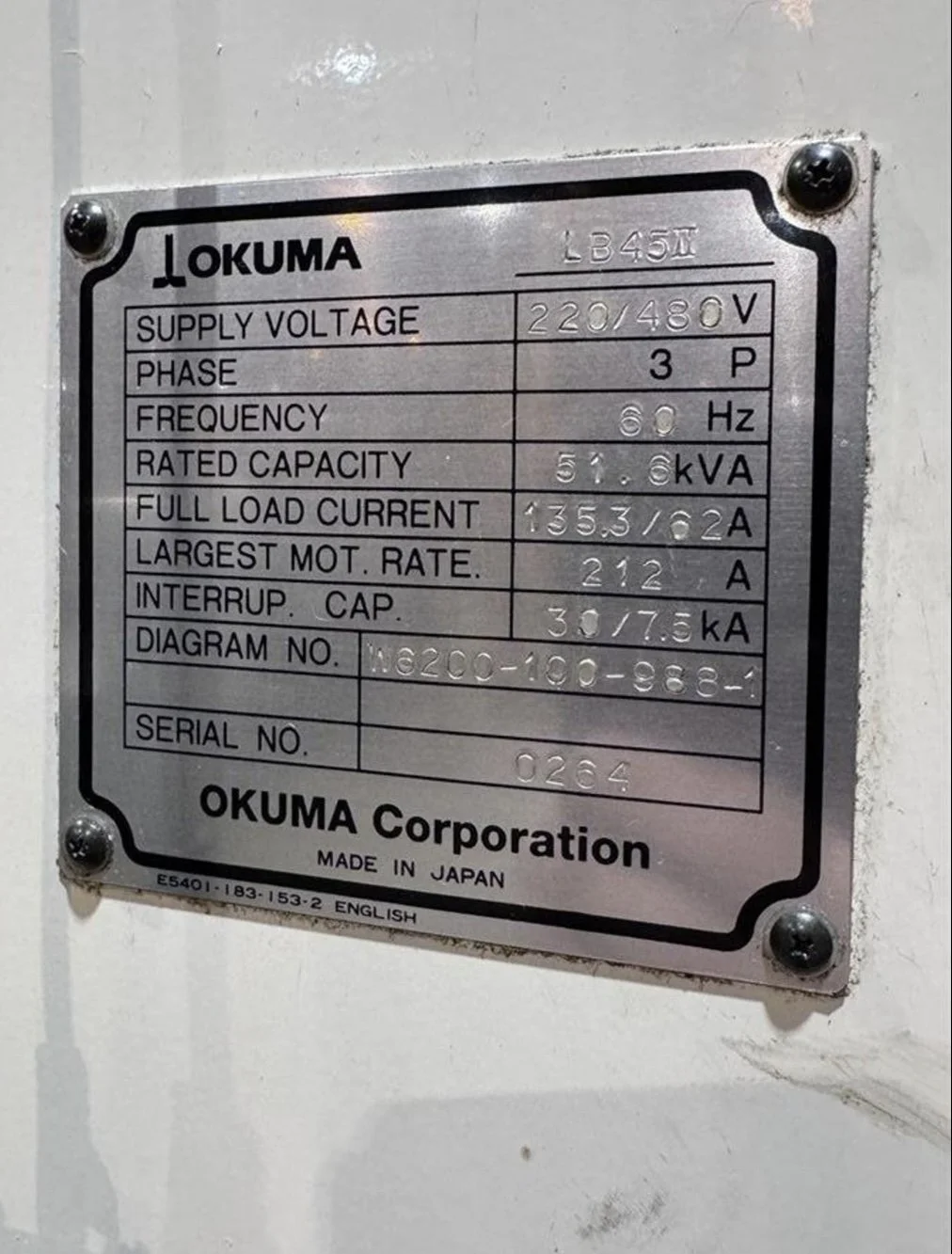

Manufacturer: OKUMA Corporation

Model: LB45II

Serial Number: 0264

Control: OKUMA OSP-U100L CNC Control

Origin: Japan

Maximum Swing Over Bed: 35.4 in (≈ 900 mm)

Maximum Turning Diameter: 26 in (≈ 660 mm)

Maximum Distance Between Centers: 78 in (≈ 1.98 meters)

Bed Type: Heavy-Duty Flatbed

Spindle Bore (Bar Capacity): 4.13 in (≈ 105 mm)

Spindle Nose: A2-11

Maximum Spindle Speed: 2,000 RPM

Main Motor Power: Approx. 40 HP

Voltage: 220/480V

Phase: 3-Phase

Frequency: 60 Hz

Rated Capacity: 51.6 kVA

Full Load Current: 135.3 / 62 A

Largest Motor Rating: 212 A

Interrupt Capacity: 30 / 75 kA

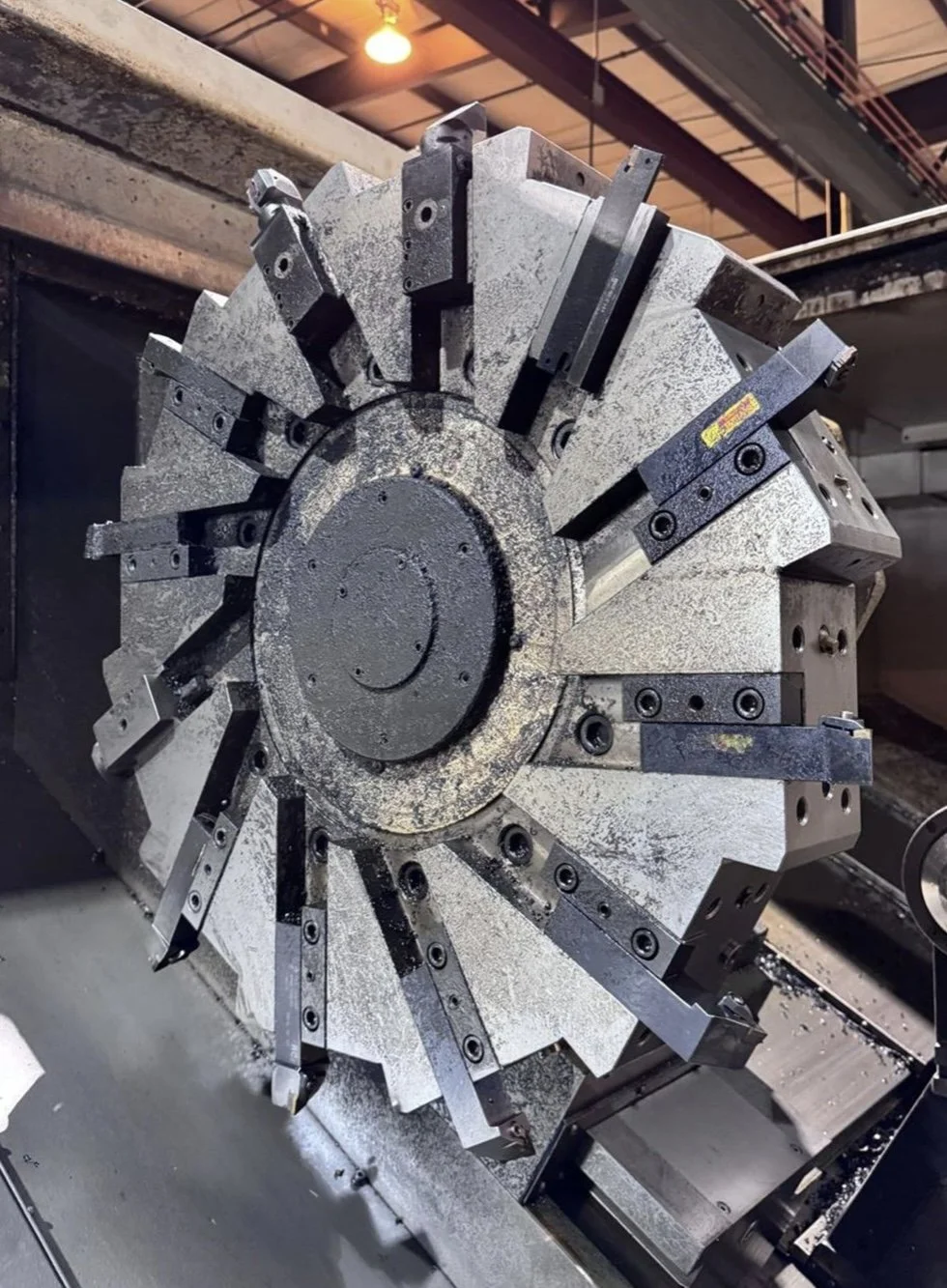

Stations: 12-Position Bi-Directional Turret

Type: Heavy-Duty Servo Driven

Rapid Traverse (X-Axis): 472 IPM (≈ 12 m/min)

Rapid Traverse (Z-Axis): 472 IPM (≈ 12 m/min)

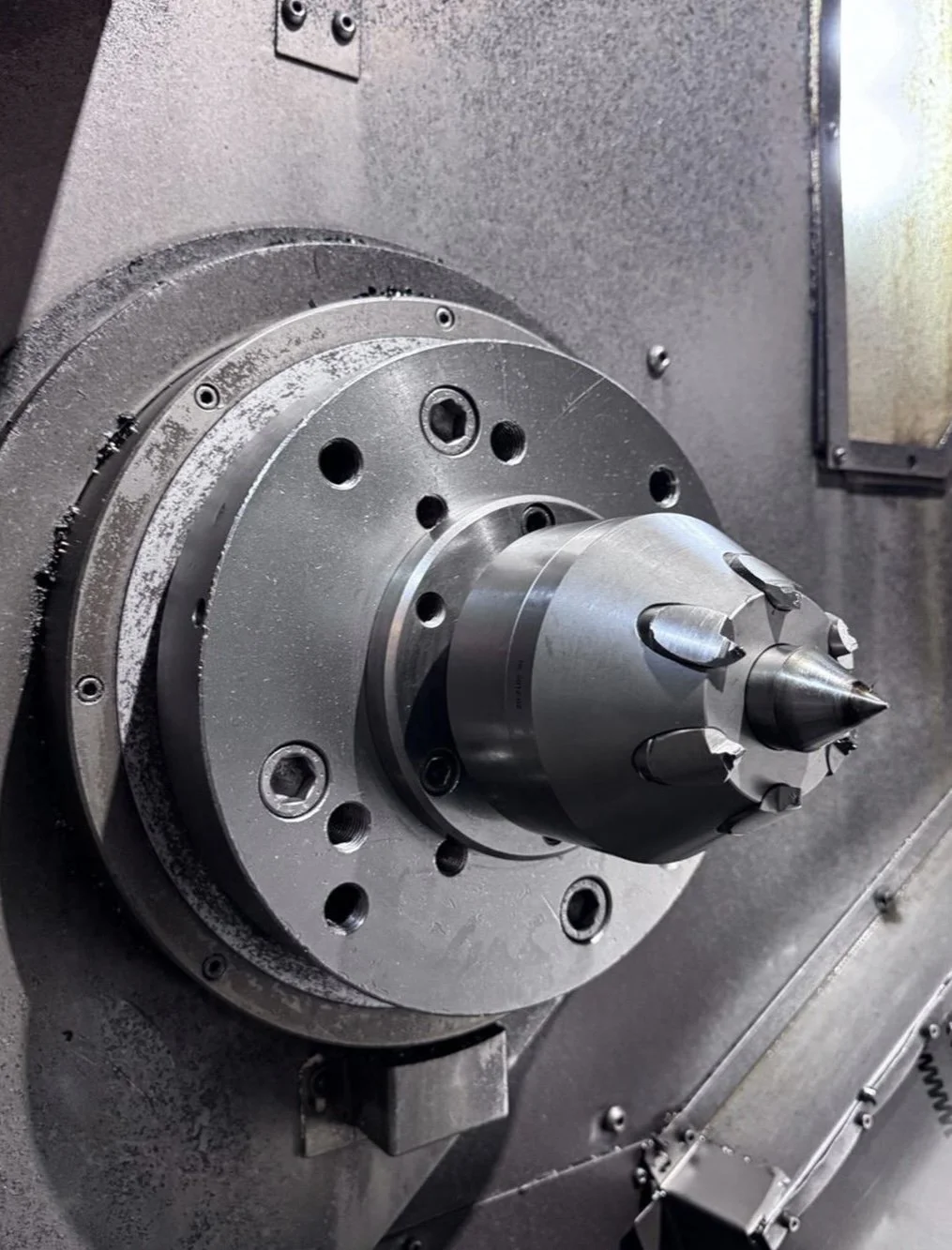

Type: Programmable Heavy-Duty Tailstock

Quill Travel: Long-stroke hydraulic quill for extended part support

Approx. Weight: 27,000 lbs (≈ 12,250 kg)

Overall Dimensions: Provided upon request

OKUMA OSP-U100L CNC Control

3-Jaw Hydraulic Chuck

Heavy-Duty Programmable Tailstock

Hydraulic Steady Rest

Chip Conveyor

TRION AIR BOSS Mist Collector

All Available Manuals

480V, 3-Phase Power Configuration

The OKUMA LB45II is a proven, heavy-duty turning center built for demanding machining environments.

With its massive cast-iron structure, rigid headstock, and precision flatbed, this machine offers outstanding stability for large-diameter and long-length workpieces.

The OSP-U100L control provides:

✔ Reliable operation

✔ Simplified programming

✔ Accurate diagnostics

✔ Consistent machining performance

With its hydraulic steady rest and programmable tailstock, the machine ensures maximum rigidity and accuracy during heavy turning operations.

This machine is in excellent working condition, clean, inspected, and ready for immediate shipment.

Featuring a heavy-duty slant bed design and equipped with the reliable FANUC 0T CNC Control. This machine is well-suited for high-volume and large-part turning applications.

MACHINE SPECIFICATIONS

Manufacturer: Leadwell

Model: LTC-30P

Control System: FANUC 0T CNC Control

CAPACITY

Maximum Swing Over Bed: 25.5 in. (Approx. 650 mm)

Maximum Turning Diameter: 18.9 in. (Approx. 480 mm)

Maximum Turning Length: Up to 55 in. / 1400 mm (Long Bed Models)

Distance Between Centers: Up to 62 in. (Contact for specific bed length)

SPINDLE

Spindle Bore (Bar Capacity): 3.7 in. (94 mm) - Note: Bar capacity may vary, please confirm

Spindle Nose: A2-8 (Typical)

Maximum Spindle Speed: 2,500 - 3,000 RPM

Main Motor Power: 35 HP (Approx.)

TURRET

Tool Stations: 12 Position Bi-Directional Turret

FEED RATES

Rapid Traverse Rate (X-Axis): 393 IPM (Approx. 10 m/min)

Rapid Traverse Rate (Z-Axis): 472 IPM (Approx. 12 m/min)

MACHINE DIMENSIONS AND WEIGHT

Approximate Machine Weight: 15,640 lbs (7,094 kg) -

EQUIPPED WITH

* CNC Control: FANUC 0T CNC Control

* Chuck: 3-JAW HYDRAULIC CHUCK

* Power: 575V Electrical Configuration (3 Phase)

* Tailstock: Heavy-Duty Tailstock

* Chip Management: Chip Conveyor

* Tooling: Basic Turret Tooling

* Documentation: All Available Manuals

MACHINE OVERVIEW

The Leadwell LTC-30P is a highly rigid CNC turning center built on a 45° slant bed cast iron base, ensuring superior stability and efficient chip evacuation. The combination of a powerful spindle, the robust FANUC 0T control, and high rapid traverse rates makes this machine an excellent workhorse for both heavy material removal and accurate, high-production turning of long shafts and large-diameter parts. It is currently available for inspection.

⸻

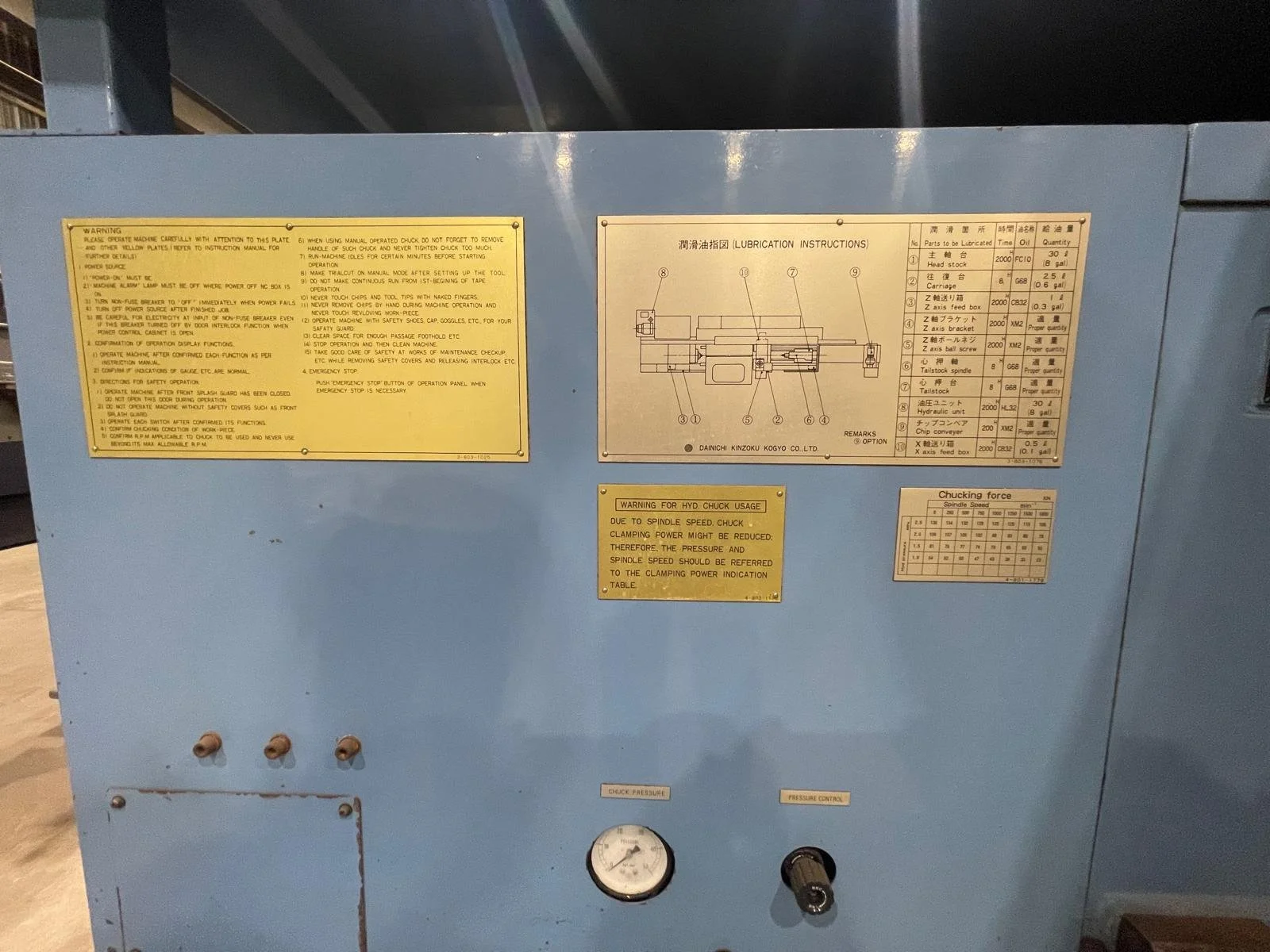

MACHINE SPECIFICATIONS

Manufacturer: Dainichi

Model: MG 65 X 140

Year of Manufacture: 1999

Serial Number: 29172

⸻

CONTROL SYSTEM

FANUC Series 18-T CNC Control

⸻

CAPACITY

Swing Over Bed: 25.5 in. (650 mm)

Distance Between Centers: 55 in. (1400 mm)

⸻

SPINDLE

Spindle Bore: 3.3 in. (85 mm)

Spindle Nose: A1-11

Spindle Speed Range: 1 - 1,800 RPM

Main Motor Power: 20 HP

⸻

TURRET

Turret Type/Stations: 6 Position Universal Turret

⸻

FEED RATES

Rapid Traverse Rate: 6 m/min

⸻

EQUIPPED WITH

* Hydraulic Chuck: KITAGAWA B18A11 3-JAW HYDRAULIC CHUCK

* Work Support: Heavy-Duty Steady Rest (11.8 in. capacity)

* Chip Management: ENOMOTO Chip Conveyor (Model: MG65 (75)-150)

* Documentation: Complete set of Maintenance Manuals (including FANUC Series 18/160/180-MODEL C)

* Tooling: Included Tool Holders

* Electrical Requirement: 480 V, 3 PH, 60 HZ

⸻

MACHINE OVERVIEW

The Dainichi MG 65 X 140 is a heavy-duty flat-bed CNC lathe renowned for its solid construction and stability, making it perfectly suited for large-diameter and shaft work. Built on a massive casting, it ensures maximum rigidity and dampens vibration for high-precision turning results. Equipped with a powerful main motor and a reliable FANUC 18-T control, this machine delivers the torque and control required for demanding production environments. It is currently available for inspection.

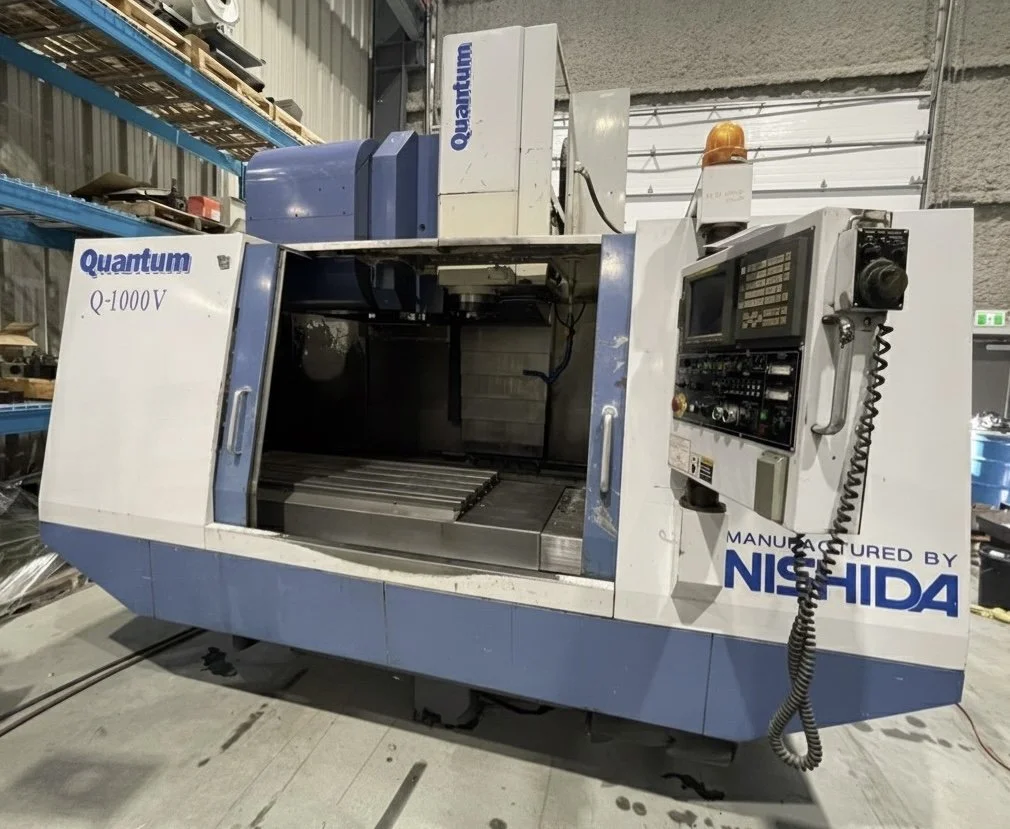

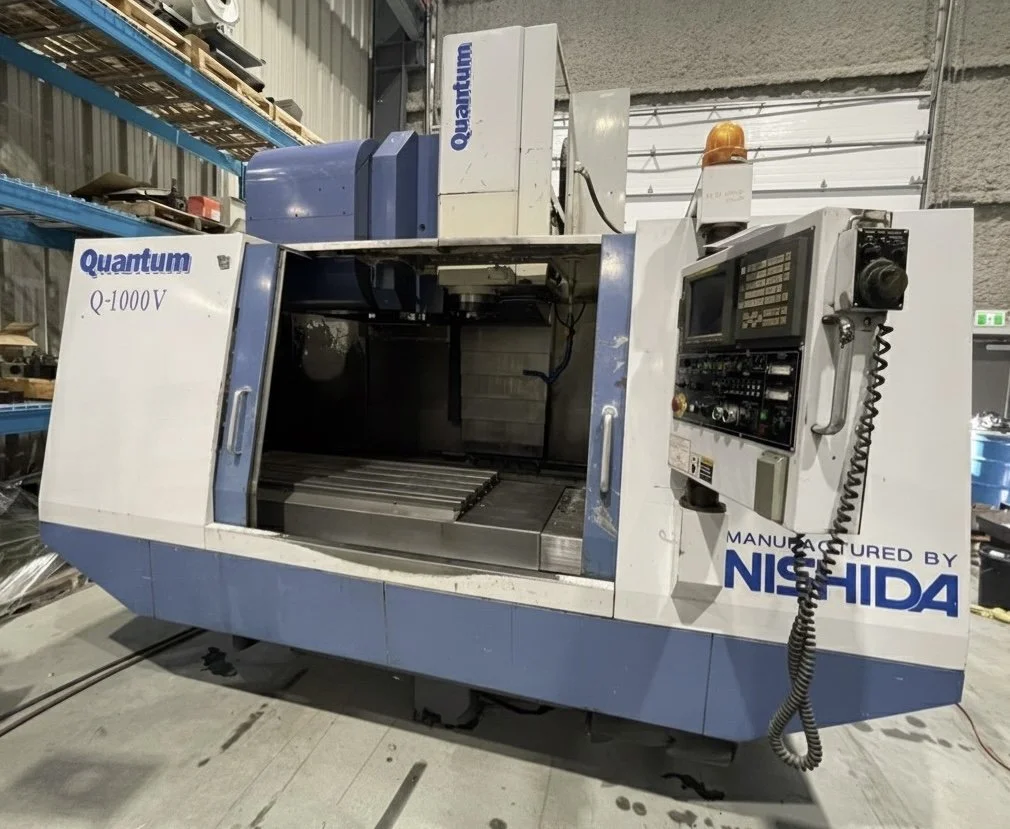

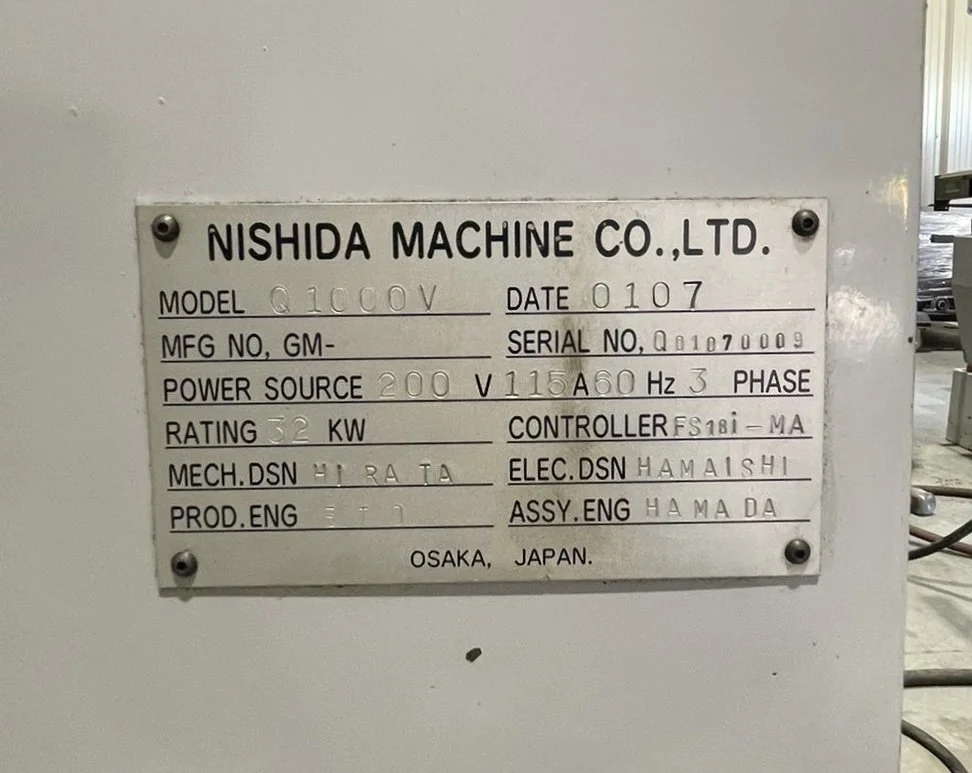

Manufacturer: Nishida Machine Co., Ltd.

Model: Q-1000V

Serial Number: Q01070009

Date of Manufacture: January 2007

Place of Manufacture: Osaka, Japan

⸻

SPECIFICATIONS

Axis Travels

X-Axis Travel: 1,067 mm (42”)

Y-Axis Travel: 610 mm (24”)

Z-Axis Travel: 650 mm (25.6”)

Table

Table Size (L × W): 1,397 × 599 mm (55” × 23.6”)

Table Top to Spindle Nose: 160 – 810 mm (6.3” – 31.9”)

Maximum Table Load: 998 kg (2,200 lbs)

Spindle

Spindle Taper: CAT 50

Spindle Speed Range: 50 – 6,000 rpm

Spindle Motor Power: 25 HP (18.6 kW)

Power Supply: 200 V, 115 A, 60 Hz, 3 Phase

Total Power Rating: 32 kW

Coolant Through Spindle (CTS): Standard

Feed Rates

Rapid Traverse (X/Y Axes): 787 IPM (20 m/min)

Rapid Traverse (Z Axis): 591 IPM (15 m/min)

Cutting Feed Rate: 0.1 – 393 IPM (2.5 – 10 m/min)

Automatic Tool Changer

Tool Capacity: 32 Tools (Side-Mount Type)

Tool Taper: CAT 50

Tool Change Time: Approx. 2.8 seconds

Maximum Tool Weight: 6.8 kg (15 lbs)

⸻

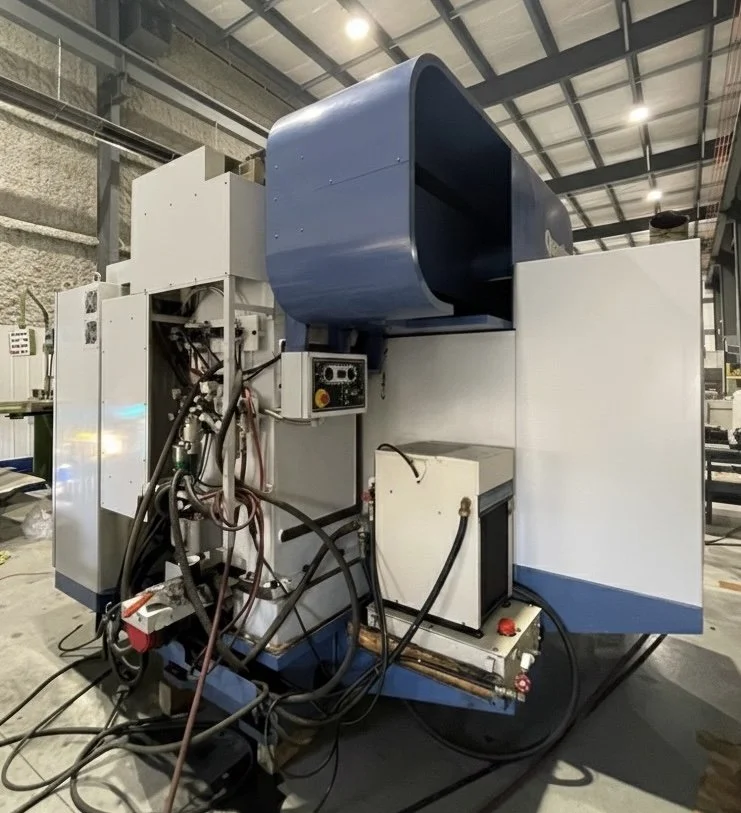

MACHINE DIMENSIONS AND WEIGHT

Overall Dimensions (W × D × H): 3,810 × 2,540 × 2,740 mm (150” × 100” × 108”)

Approximate Machine Weight: 8,618 kg (19,000 lbs)

⸻

EQUIPPED WITH

• FANUC FS18i-MA CNC Control

• Coolant Through Spindle System (CTS)

• 32-Station Automatic Tool Changer (SMTC)

• Rigid Tapping Function

• Spindle Chiller Unit

• Lift-Up Chip Conveyor

• Full Coolant Enclosure and Chip Guarding

• Pendant-Mounted CNC Control Panel

• Work Light and Air Blast System

• Machine Documentation and Operator Manuals

⸻

MACHINE OVERVIEW

The Nishida Q-1000V Vertical Machining Centre is a precision-engineered, heavy-duty CNC machining platform designed for superior rigidity, reliability, and accuracy.

Built on a robust cast-iron base and column, it offers excellent vibration damping and thermal stability for consistent machining precision.

Equipped with a CAT 50 spindle, 25 HP motor, and Fanuc FS18i-MA CNC control, this model delivers strong torque performance and smooth motion control for demanding production and toolroom applications.

The integration of through-spindle coolant, rigid tapping, and a high-capacity automatic tool changer makes it ideal for a wide range of precision machining operations, including mold, die, and component manufacturing.

No results match your search. Try removing a few filters.