Image 1 of 5

Image 1 of 5

Image 2 of 5

Image 2 of 5

Image 3 of 5

Image 3 of 5

Image 4 of 5

Image 4 of 5

Image 5 of 5

Image 5 of 5

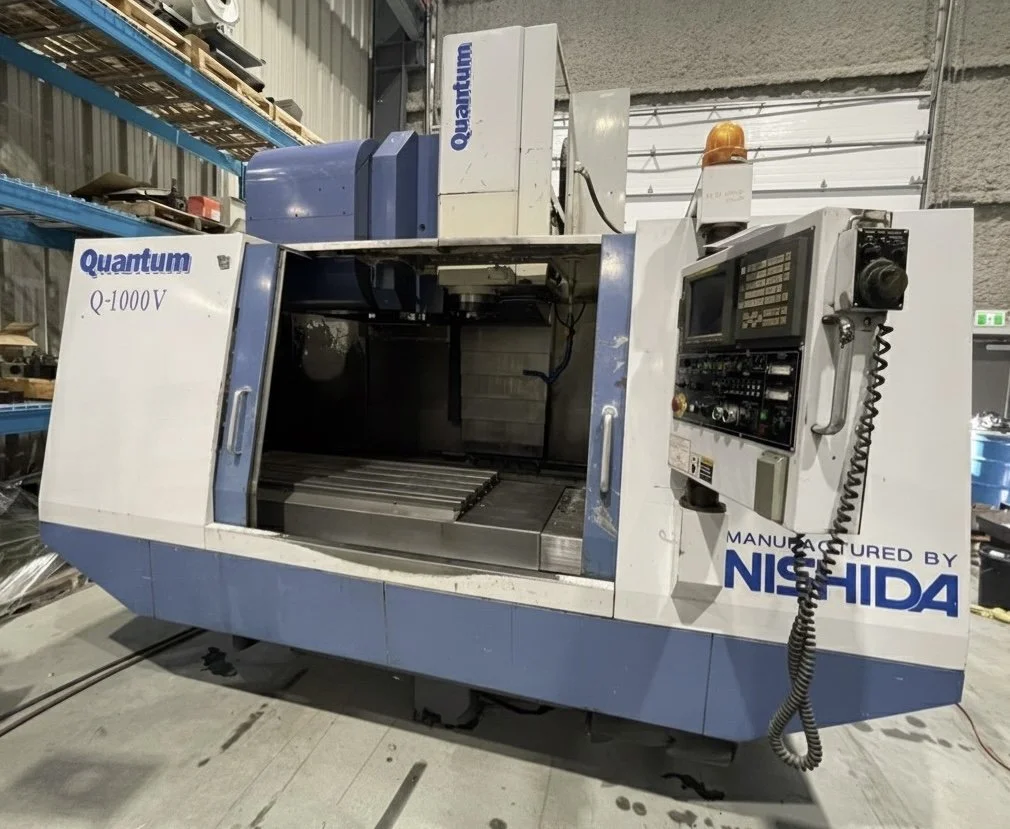

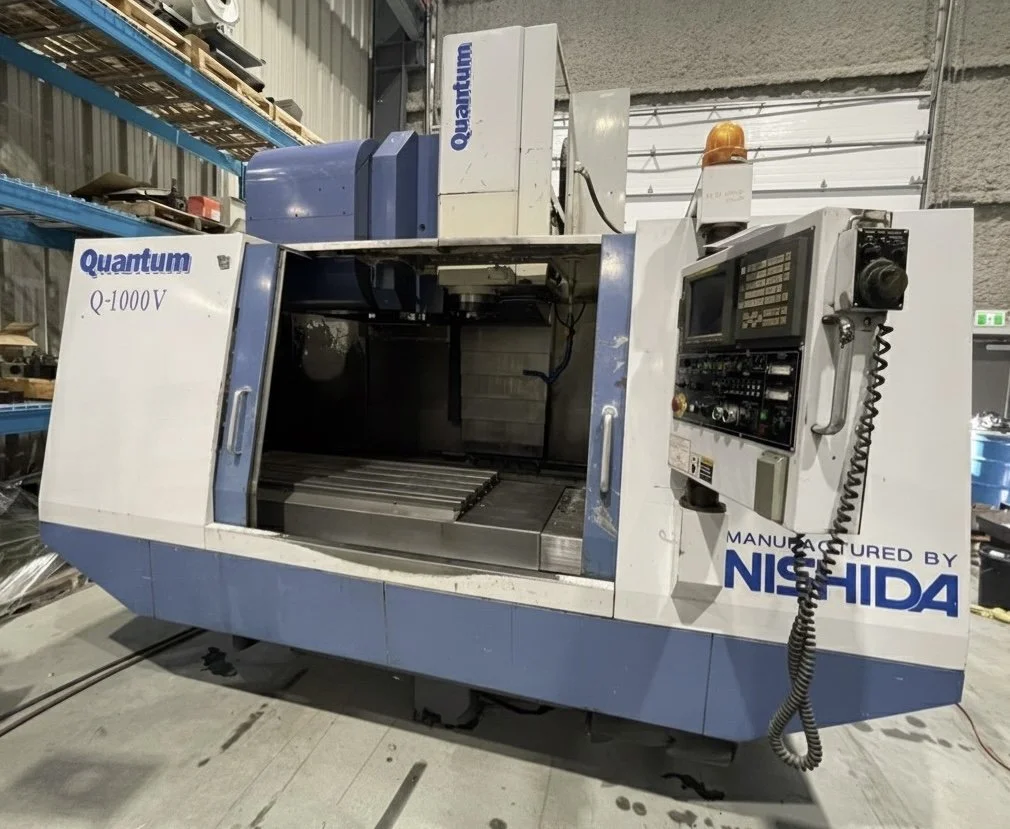

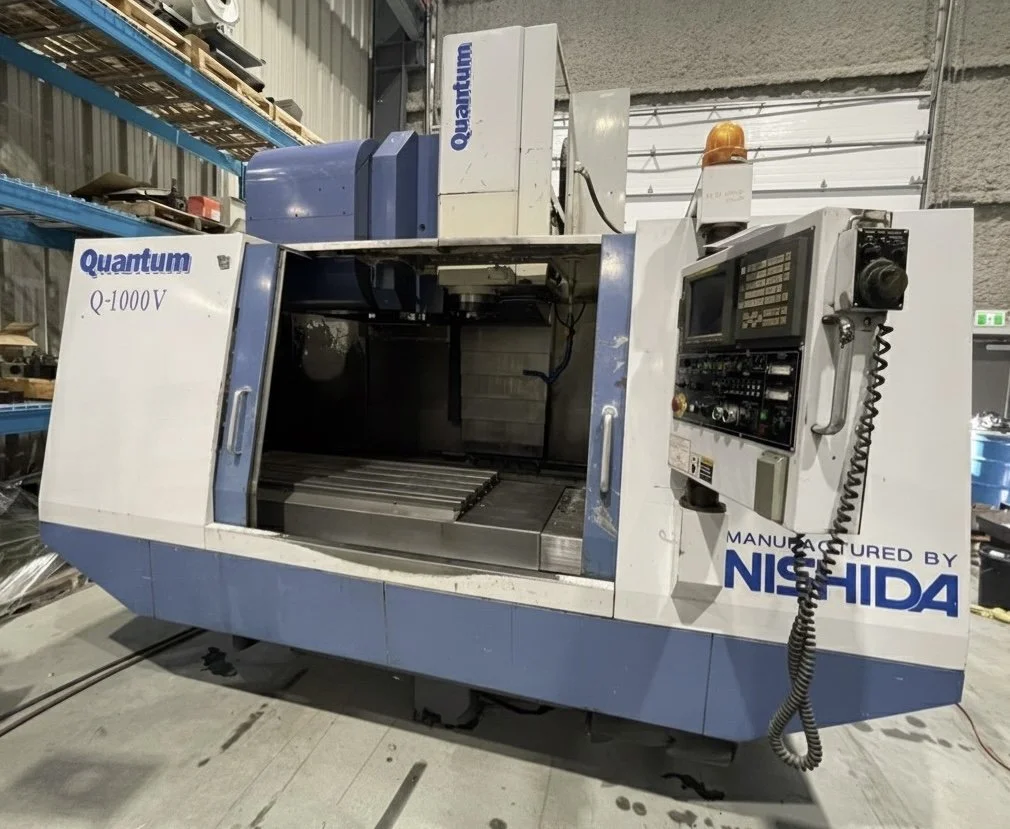

NISHIDA Q-1000V VERTICAL MACHINING CENTRE

SOLD!!

Machine dispatched in seacan to India. arriving soon.

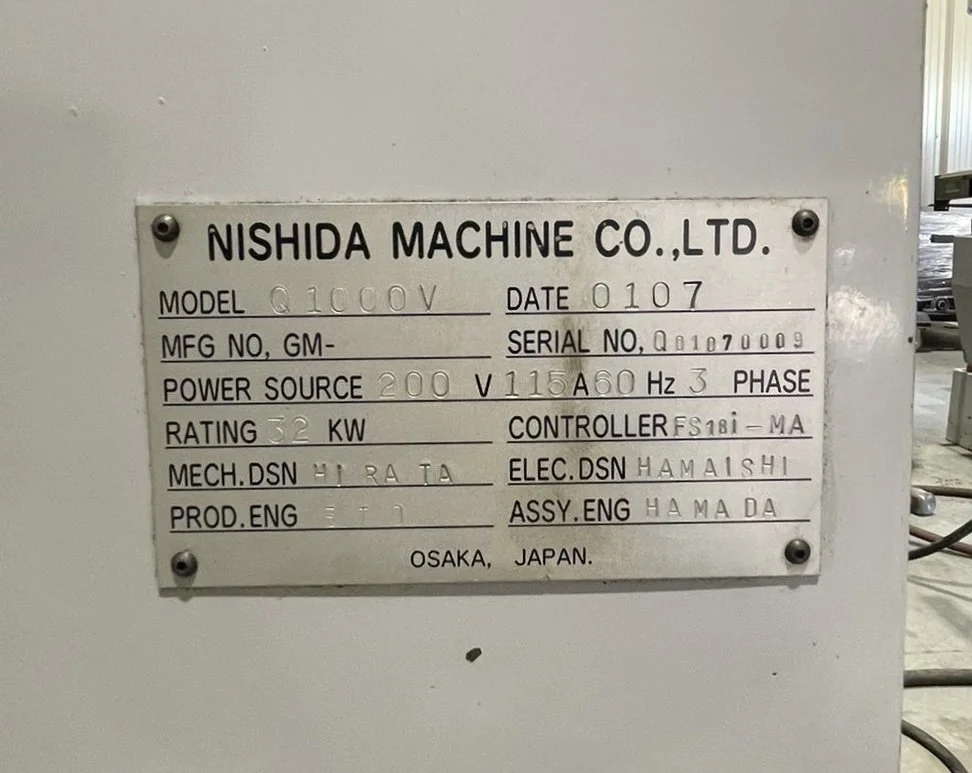

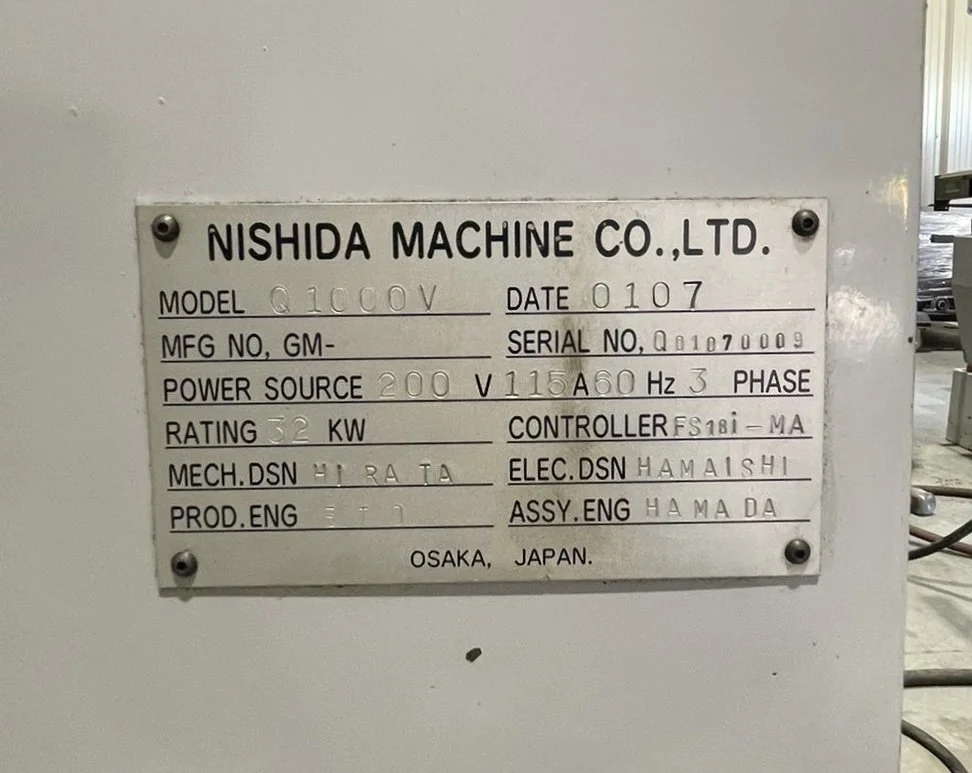

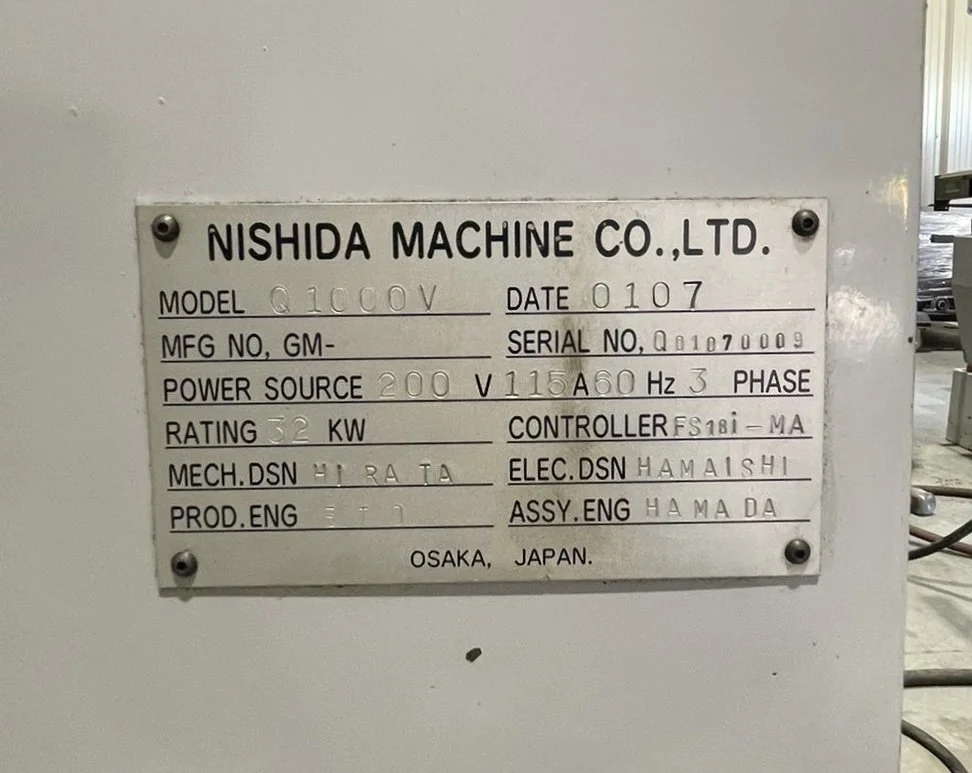

Manufacturer: Nishida Machine Co., Ltd.

Model: Q-1000V

Serial Number: Q01070009

Date of Manufacture: January 2007

Place of Manufacture: Osaka, Japan

⸻

SPECIFICATIONS

Axis Travels

X-Axis Travel: 1,067 mm (42”)

Y-Axis Travel: 610 mm (24”)

Z-Axis Travel: 650 mm (25.6”)

Table

Table Size (L × W): 1,397 × 599 mm (55” × 23.6”)

Table Top to Spindle Nose: 160 – 810 mm (6.3” – 31.9”)

Maximum Table Load: 998 kg (2,200 lbs)

Spindle

Spindle Taper: CAT 50

Spindle Speed Range: 50 – 6,000 rpm

Spindle Motor Power: 25 HP (18.6 kW)

Power Supply: 200 V, 115 A, 60 Hz, 3 Phase

Total Power Rating: 32 kW

Coolant Through Spindle (CTS): Standard

Feed Rates

Rapid Traverse (X/Y Axes): 787 IPM (20 m/min)

Rapid Traverse (Z Axis): 591 IPM (15 m/min)

Cutting Feed Rate: 0.1 – 393 IPM (2.5 – 10 m/min)

Automatic Tool Changer

Tool Capacity: 32 Tools (Side-Mount Type)

Tool Taper: CAT 50

Tool Change Time: Approx. 2.8 seconds

Maximum Tool Weight: 6.8 kg (15 lbs)

⸻

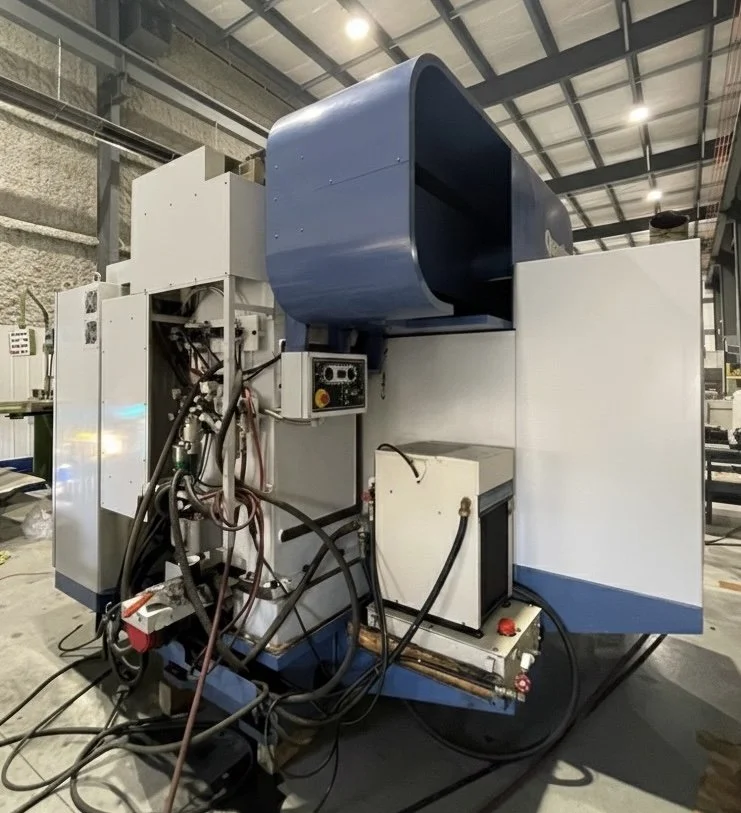

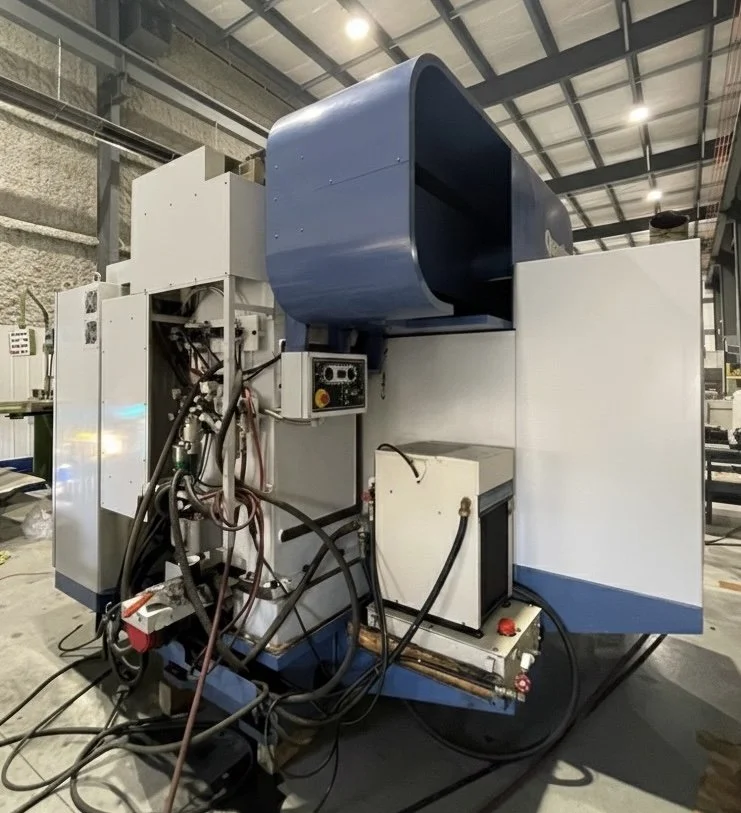

MACHINE DIMENSIONS AND WEIGHT

Overall Dimensions (W × D × H): 3,810 × 2,540 × 2,740 mm (150” × 100” × 108”)

Approximate Machine Weight: 8,618 kg (19,000 lbs)

⸻

EQUIPPED WITH

• FANUC FS18i-MA CNC Control

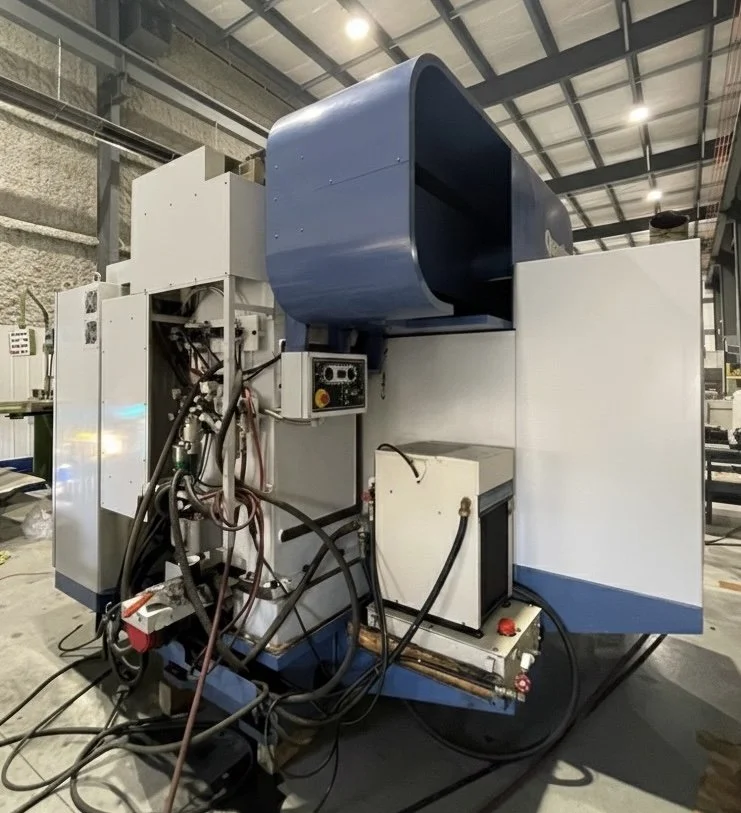

• Coolant Through Spindle System (CTS)

• 32-Station Automatic Tool Changer (SMTC)

• Rigid Tapping Function

• Spindle Chiller Unit

• Lift-Up Chip Conveyor

• Full Coolant Enclosure and Chip Guarding

• Pendant-Mounted CNC Control Panel

• Work Light and Air Blast System

• Machine Documentation and Operator Manuals

⸻

MACHINE OVERVIEW

The Nishida Q-1000V Vertical Machining Centre is a precision-engineered, heavy-duty CNC machining platform designed for superior rigidity, reliability, and accuracy.

Built on a robust cast-iron base and column, it offers excellent vibration damping and thermal stability for consistent machining precision.

Equipped with a CAT 50 spindle, 25 HP motor, and Fanuc FS18i-MA CNC control, this model delivers strong torque performance and smooth motion control for demanding production and toolroom applications.

The integration of through-spindle coolant, rigid tapping, and a high-capacity automatic tool changer makes it ideal for a wide range of precision machining operations, including mold, die, and component manufacturing.

SOLD!!

Machine dispatched in seacan to India. arriving soon.

Manufacturer: Nishida Machine Co., Ltd.

Model: Q-1000V

Serial Number: Q01070009

Date of Manufacture: January 2007

Place of Manufacture: Osaka, Japan

⸻

SPECIFICATIONS

Axis Travels

X-Axis Travel: 1,067 mm (42”)

Y-Axis Travel: 610 mm (24”)

Z-Axis Travel: 650 mm (25.6”)

Table

Table Size (L × W): 1,397 × 599 mm (55” × 23.6”)

Table Top to Spindle Nose: 160 – 810 mm (6.3” – 31.9”)

Maximum Table Load: 998 kg (2,200 lbs)

Spindle

Spindle Taper: CAT 50

Spindle Speed Range: 50 – 6,000 rpm

Spindle Motor Power: 25 HP (18.6 kW)

Power Supply: 200 V, 115 A, 60 Hz, 3 Phase

Total Power Rating: 32 kW

Coolant Through Spindle (CTS): Standard

Feed Rates

Rapid Traverse (X/Y Axes): 787 IPM (20 m/min)

Rapid Traverse (Z Axis): 591 IPM (15 m/min)

Cutting Feed Rate: 0.1 – 393 IPM (2.5 – 10 m/min)

Automatic Tool Changer

Tool Capacity: 32 Tools (Side-Mount Type)

Tool Taper: CAT 50

Tool Change Time: Approx. 2.8 seconds

Maximum Tool Weight: 6.8 kg (15 lbs)

⸻

MACHINE DIMENSIONS AND WEIGHT

Overall Dimensions (W × D × H): 3,810 × 2,540 × 2,740 mm (150” × 100” × 108”)

Approximate Machine Weight: 8,618 kg (19,000 lbs)

⸻

EQUIPPED WITH

• FANUC FS18i-MA CNC Control

• Coolant Through Spindle System (CTS)

• 32-Station Automatic Tool Changer (SMTC)

• Rigid Tapping Function

• Spindle Chiller Unit

• Lift-Up Chip Conveyor

• Full Coolant Enclosure and Chip Guarding

• Pendant-Mounted CNC Control Panel

• Work Light and Air Blast System

• Machine Documentation and Operator Manuals

⸻

MACHINE OVERVIEW

The Nishida Q-1000V Vertical Machining Centre is a precision-engineered, heavy-duty CNC machining platform designed for superior rigidity, reliability, and accuracy.

Built on a robust cast-iron base and column, it offers excellent vibration damping and thermal stability for consistent machining precision.

Equipped with a CAT 50 spindle, 25 HP motor, and Fanuc FS18i-MA CNC control, this model delivers strong torque performance and smooth motion control for demanding production and toolroom applications.

The integration of through-spindle coolant, rigid tapping, and a high-capacity automatic tool changer makes it ideal for a wide range of precision machining operations, including mold, die, and component manufacturing.